Pack The

Future

2023

Gewinner 2018

Kategorie: Ökodesign

Kategorie : Ökodesign Special Award

Kategorie : Produktschutz

Kategorie : Verbrauchernutzen

Kategorie : Save Food

Jokey Plastik Wipperfürth GmbH, (Kategorie Ökodesign)

Verpackung in Sekundärrohstoffen aus dem Post-Consumer-Bereich

Es ist keine wirkliche Innovation für Jokey. Seit 1991 produzieren wir Verpackungen aus post-consumer Sekundärrohstoffen. Leider ohne durchschlagenden Erfolg, da die Akzeptanz vonVerpackungen aus Sekundärrohstoffen im Markt nicht sehr groß ist. Dabei wäre die Verarbeitung von Rezyklaten in diesen Verpackungen ein wichtiger Schritt für die Kreislaufwirtschaft. Anstelle das Gebinde komplett aus grauen Rezyklaten zu fertigen, bieten wir unseren Abnehmern die Möglichkeit der individuellen Farbgestaltung des Deckels und des Bügels. Beide werden physikalisch hohen Anforderungen unterworfen und bieten nebender visuellen Wahrnehmung auch Sicherheit imtäglichen Gebrauch der Verpackungen (Tragesicherheit und mehrfaches Öffnen und Schließen). Wir dekorieren das Gebinde zusätzlich mit einem materialhomogenen PP-IML und geben dem „grauen“ Gebinde eine attraktive und individuelle Visitenkarte am POS. Selbstverständlich lassen sich – wie in diesem IML – auch smarte Eigenschaften wie Duft, Wassermarken und vieleandere Features einbauen. Der Eimer ist in diesem Fall zu 100 % aus Sekundärrohstoffen gefertigt und sein „graues“ Erscheinungsbild ist dann auch schon fast nicht mehr sichtbar. Deckel und Bügel können selbstverständlich auch aus Rezyklaten gefertigt werden.Wir werben nach Außen für den Einsatz von Sekundärrohstoffen mit der Initiative „Grau ist das neue Grün“ seit Juni 2018.

Zielbranchen: Non-Food-Füllstoffe wie Klebstoffe, Farben und Lacke

Nordfolien GmbH, (Kategorie Ökodesign)

Eine Folie, die bis zu 80% recycelten Anteil enthält.

Nordfolien GmbH, (Kategorie Ökodesign)

Eine Folie, die bis zu 80% recycelten Anteil enthält.

Verpackungen nehmen in der öffentlichen Nachhaltigkeitsdiskussion einen hohen Stellenwert ein und sind häufig Gegenstand von Kritik. Der Einsatz von Recyclingmaterial wird von einer Vielzahl an Initiativen unter Beteiligung namhafter Brand Owner aber auch durch die neuere Gesetzgebung gefördert und gefordert. Nordfoliens Norec®-Recyclingverfahren erfüllt alle Anforderungen für die Wiederverwendungin hochwertigen Verpackungen. Dies ist die Basis für die neue Produktgruppe NorDiFill®-ECO. EineKonsumverpackungsfolie mit einem Recyclingmaterialanteil von bis zu 80%. Im Nordfolien Norec®Prozess werden Additive, Wachse, kurz kettige Molekülbestandteile sowie Druckfarben und Lacke ausgewaschen. Für die NorDiFill®-ECO Folien bedeutet dies ein außerordentlich hohes Qualitätsniveau und eine exzellente Möglichkeit zur Einhaltung von Nachhaltigkeitszielen sowie eine hervorragende Produktpräsentation am POS:

- Geeignet für hochwertige, konsumverpackungstaugliche Bedruckung

- Hohe mechanische Festigkeit

- Geruchsfrei

- Gleichmäßige Färbung (frei von Einfärbungseffekten)

- Hohe Nachhaltigkeit

- Geringerer Gesamtenergieverbrauch

- 80 % weniger fossile Ressourcen

- Erheblich verringerte CO2 Emission

- Keine Änderungen in Dicke, Abmessungen,

- Verarbeitung

- Gute Restentleerbarkeit.

Zielbranchen: Industrie- und Non-Food-Konsumverpackungen, z. B. Düngemittel, Waschmittel, Waschpulver, Chemikalien, Baustoffe…….

Heinz Plastics Böhm GmbH, (Kategorie Ökodesign)

Kappe aus 100% recyceltem Polypropylen

Erster voll funktionsfähiger Verschluss, der zu 100% aus Polypropylen-Recyclat besteht und dessen Rohstoff zu 100% aus dem „gelben Sack“ gewonnen wird. Das Unternehmen Werner & Mertz als Entwicklungspartner und Pionier in Sachen Nachhaltigkeitsetzt im Rahmen seiner Recyclat-Initiative bei seinen Produkten der Marke Frosch serienmäßig Flaschen aus Recycling-Material ein und verschließt diese nun mit dem Verschluss von Heinz Plastics Böhm. Selbst die grüne Farbe des Klappverschlusses ist nachhaltig! Dieser Verschluss kann ebenso wieder recycelt werden, so dass ein geschlossener Material-Kreislauf entsteht, der die Umwelt kaum belastet.

Zielbranchen: Kosmetik, Haushaltsprodukte, Reinigungsprodukte, Freizeit und Gartenbau

Incoplas SA, (Kategorie Ökodesign)

HDPE-Kanister mit mindestens 50% post consumer recyceltem Material

Das „rPE-Flaschensortiment“ besteht aus HDPE-Harz, in das mindestens 50 % Post Consumer Recycling (PCR)-Material eingearbeitet wurde.Bei der Verarbeitung dieses von Total gelieferten Materials gelingt es uns, die mechanischen und technischen Eigenschaften der Verpackung zu erhalten und sogar zu verbessern. Während Kunden bei der Verwendung von PCR-Material in der Regel bisher Qualitätsverluste befürchteten, können wir ihnen nun eine hohe und gleich bleibende Flaschenqualität garantieren. Dies ist ein überzeugendes Argument für die Kunden, den Einsatz von PCR Material zu fördern.

Zielbranchen: Automotive Maintenance Produkte, usw.

Groupe Barbier, (Kategorie Ökodesignn)

Produktgruppierungsfolie, die bei niedrigeren Temperaturen schrumpft

- Temperaturreduzierung zwischen 20 und 40°C= Energieeinsparung

- Reduzierung der Dicke um ca. 10 μm = Materialeinsparung(-18 %)

- Reduzierung des CO2-Fußabdrucks durch Einsatzvon 20 % recyceltem Material = Umwelteinsparung(C02 -17 %)

- Dies ändert nicht die technischen,

- Leicht teurer – um 4 %

optischenund mechanischen Eigenschaften der Folie.

Es ist daher die Kombination aus technischem Know-how und dem Wunsch der Hersteller, ihre Kohlenstoffbelastung zu reduzieren, die den Erfolg dieser niedrigschmelzenden Folie ausmacht.

Zielbranchen: Getränke (Wasser, Milch, Bier, Suppe, Sirup), Konserven (Gemüse, Tiernahrung….), Hygiene, Gefrieren, Kompost, Pellets, usw.

ALPLA Werke Alwin Lehner GmbH & Co KG, (SPECIAL AWARD)

Die erste recycelbare Flasche, in der 25% des an Stränden gesammelten Kunststoffabfällen verwendet werden.

Auch andere Firmen haben bereits Kunststoffabfälle aus dem Meer verwendet, aber in geringeren Mengen – dies ist die erste Flasche, deren Granulat 25 % Material von Stränden beinhaltet und die recycelbar ist. Unser Ziel ist ein Kreislaufsystem. Für die Shampoo Marke „Head & Shoulders“ haben TerraCycle, Suez, ALPLA und Procter & Gamble gemeinsam die weltweit erste recycelbare Flasche aus „Beach Plastic“ hergestellt. Hunderte NGOs und tausende Freiwillige sind Teil der Initiative und sammeln an Stränden Kunststoffabfälle zum Recyceln. Aufgrund von Umwelteinflüssen wie UV-Strahlungund Salzwasser ist Kunststoff aus dem Meer besonders schwierig wiederzuverwenden. Das Granulat muss gut gereinigt werden, um Schmutz und Mikroorganismen zu entfernen. Um den Kunststoff zur Weiterverarbeitung vorzubereiten, bedurfte es einer sorgfältigen Entwicklung. Was Produktschutz und Verbrauchersicherheit angeht, so hat man sichergestellt,dass die neue Verpackung denselben hohen Standards entspricht wie die herkömmlichen „Head & Shoulders“-Flaschen. Im Juni 2017 wurde das Produkt in Frankreich eingeführt. Die Flasche soll nicht nur mithelfen, Kunststoffabfälle von den Stränden zu beseitigen– sie soll auch das Bewusstsein der Verbraucherstärken und sie dazu anregen, sich am Recycling zu beteiligen.

Zielbranchen: Körperpflege und Schönheitspflege

RPC Bramlage, (Kategorie Produktschutz)

Verpackung mit recyceltem Material, die den Vertrieb von konservierungsmittelfreier Kosmetikcreme ermöglicht.

RPC Bramlage hat in Zusammenarbeit mit Pierre Fabre Dermo Cosmetique eine Verpackung entwickelt, die es erlaubt, kosmetische Creme ohne Konservierungsstoffe zu vertreiben. Darüber hinausträgt diese Verpackung durch die Integration von Recyclingmaterial der Kreislaufwirtschaft Rechnung. Die Innovation liegt in der Pumpe, bei der im Druckknopf ein Endverschluss integriert ist. Die Verschlussklappe öffnet sich beim Drücken des Druckknopfes und schließt sich, wenn der Druckknopf wieder nach oben bewegt wird. Die Leistung des Endverschlusses wurde durch mikrobiologische Tests über mehrere Wochennachgewiesen. Weder bei der Pumpe noch beim Fläschchen kam es zu bakteriellen Kontaminationen. Die Pumpe besteht zu 100 % aus Kunststoff und ist zu 100 % recyclebar. Das Pumpen- und Flaschenset wurde entwickelt, um dick flüssige Kosmetikprodukte mit sehr effizienten Abgaberaten dosieren zu können. Das reduziert die in der Flasche verbleibende Restmenge. Bei der Airless-Flasche kann recyceltes Material in die äußere Schicht integriert werden. Zwischen diesem recycelten Material und der Creme gibtes eine Sperrschicht, die die kosmetische Creme vor einer möglichen Migration des recycelten Materials schützt. Diese Verpackung ist hochinnovativ, da sie eine konservierungsmittelfreie Kosmetikcreme und die Integration von Recyclingmaterial als Teil der Kreislaufwirtschaft kombiniert.

Zielbereiche: Körper- und Schönheitspflege

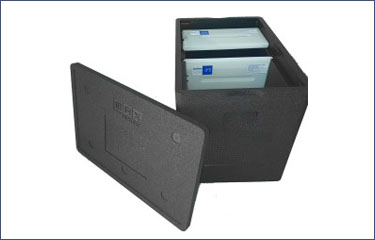

OHLRO Hartschaum GmbH, (Kategorie Produktschutz)

Eine Transportbox, mit der die Temperatur für mindestens 250 Stunden zwischen 2° und 8° C gehalten werden kann.

Unsere O-BOX H250 bietet eine neue Möglichkeit für den Transport von temperatur empfindlichen Gütern jeglicher Art, wie Pharmaprodukten, Lebensmittel und chemischen Produkten. Durch die geschickte Zusammenführung verschiedener Materialien konnten wir eine Transportboxentwickeln, mit der man in der Lage ist, die Temperatur für mindestens 250 Stunden in einem Spektrum von zum Beispiel 2° bis 8° C zuhalten. Die Box besteht aus schäumbaren Kunststoffen, welche einen positiven Wärmeleitkoeffizient besitzen. Des Weiteren haben alle Außenwände Hohlkammern, in denen sich Vakuumpaneele (VIP) befinden. Somit wird der Wärmeaustauschmit der Umwelt verhindert. Ebenfalls sorgen Latentwärmespeicher (PCM) dafür, dass die Temperaturim Inneren der Box lange stabil bleibt. Das besondere Innendesign trägt dazu bei, dass unser Prototyp bei einer Überprüfung nach dem ISTA-Sommerprofil die Temperatur über 250 Stunden zwischen 2° und 8° C gehalten hat. Aktuellbesitzt die Box ein nutzbares Innenvolumen von ca. 30 l, wobei weitere Volumina bei Bedarfmöglich sind. Ein weiterer Vorteil ist es, dass durch die Nutzung von schäumbaren Kunststoffen das Eigengewicht der Verpackung im Vergleich zu den bereits vorhandenen Lösungen deutlich reduziert ist. Die VIPs sind so geschützt, dass diese selbst bei unsachgemäßem Umgang mit der Box nicht sofort zerstört werden.

Zielbranchen: Lebensmittel, Pharmazeutika, Biotechnologie, Chemie, Medizin

RPC Bender GmbH, (Kategorie Verbrauchernutzen)

Sportverschluss für Flaschen

SecureFlip – Ein neuer innovativer, verbraucher freundlicher Flip-Top Sport-Verschluss für den Flaschenhals PCO1881. Der neue Secure Flip 1881 Sportverschluss verfügt über eine intuitive Ein-Hand-Öffnung, kombiniert mit einem modernen ergonomischen und nachhaltigen Design. Die Kappe öffnet sich mit einer Hand auf volle und stabile 180 ° und bietet dem Verbraucher einen einfachen und bequemen Zugang, sodass man während dem Sport oder einfach auf dem Weg aus dem Verschluss trinken kann. Das nachhaltige und manipulations sichere Garantieband innerhalb des Verschlusses bricht beim ersten Öffnen. Beim Secure Flip ist das Garantieband im Verschluss gut sichtbar. Dies ist ein großer Vorteil gegenüber anderen Sportverschluss-Konzepten mit einer abnehmbaren Lasche, welche vom Verbraucher weg geworfen wird und damit die Umwelt verschmutzt. Ein zweites Garantieband an der Basis des Verschlusses bleibt nach dem Abschrauben auf der Flasche und kann somit wie andere Garantiebänder von Standard-Getränkeverschlüssen auf Einweg-Plastikflaschen recycelt werden. Der Secure Flip ist derzeit von RPC Bender Frankenthal für die 1881 Mündung und in 29,25 vonanderen RPC-Werken erhältlich. Weitere Größen sind in der Entwicklung. Der neue SecureFlip kann vollständig individualisiert werden, um Kundenprodukte und Marken mit einzigartigen Farben für jede der 3 Komponenten des Verschlusseszu stärken.

Zielbranchen: Lebensmittel, insbesondere Getränkeindustrie

BETAPACK, (Kategorie Verbrauchernutzen)

Angeschlossener Flaschenverschluss

Der SNAP CLIC PELICAN ist ein neuartiger Verschluss, der sich direkt an der Flasche befindet. Es handelt sich um einen umweltschonenden Verschluss betapack_BOUCHON SNAP CLIC PELICAN 2(weniger Kunststoff bei der Verschlusskappe und weniger PET an der Flaschenmündung). Praktisch: Der Verschluss ist fest mit der Flascheverbunden. Die Kappe lässt sich um mehr als 180º neigen. Beim Wiederverschließen wird sie wieder nach vorn zurück geklappt. Auf der Vorderseite lässt sie sich leicht wieder öffnen. Hygienisch: Es ist unwahrscheinlich, dass der Verschluss zu Boden fällt oder draußen verlorengeht. Funktionell: Dieses Verschlusssystem ist einfacher zu öffnen als ein Schraubverschluss und die Verschlusskappe neigt sich nach hinten, um den Flaschenhals freizugeben. Umweltfreundlich: Der Verschluss wird systematisch zusammen mit der Flasche recycelt (100%ige Recyclingfähigkeit der Verpackung).

Zielbranchen: Lebensmittel, insbesondere Getränkeindustrie

BERNHARDT Packaging & Process, (Kategorie Verbrauchernutzen)

Eine Tasche, um Platz in Krankenhäusern zu schaffen.

Der STERI-LIQUID POUCH von BERNHARDT ist der erste 5-Liter-Beutel, der speziell für Flüssigkeiten entwickelt wurde, die sterilisiert werden müssen. Einfach in der Anwendung und aufgrund seiner Griffe oben und unten leicht zu entleeren, ausgelegt für bis zu 1,5 Stunden Autoklavenzyklus,einschließlich 30 Minuten bei 121,4 °C. Der Beutel besteht aus PA und für medizinische Anwendungen geeignetem PP. Ziel ist es, mit diesem Beutel Kanister zu ersetzen und damit das Abfallvolumen, das Krankenhäuser zu verwalten haben, um den Faktor 10 zu reduzieren.Die Anwendungen sind vielfältig und reichen von sterilem Wasser bis hin zu Dialyselösungen. Besonderes Augenmerk wurde auf die mechanische Widerstandsfähigkeit des Beutels gelegt (erbesteht Falltests aus einer Höhe von 1 Meter). Weniger Platz für leere Verpackungen bedeutet mehr Platz für wichtige Dinge und vor allem für die Patienten. Wir schätzen den jährlichen Nettogewinn für die größten Krankenhäuser auf 135 Kubikmeter, was einer Einsparung von 10 Hin- und Herfahrten von Müllwagen pro Krankenhausentspricht. In Frankreich, Deutschland und in Großbritannien ist dies vergleichbar mit dem jährlichen Müllaufkommen einer Stadt mit 100.000 Einwohnern. Der STERI-LIQUID POUCH bietet ein gutes Potenzial der thermischen Verwertung, da seine Bestandteile für eine saubere und rückstandsfreieVerbrennung ausgelegt sind. Seine Folie kann noch nicht als recycelbar angesehen werden, da die Technologie zur Trennung von Kunststoffschichten noch nicht weit genug fortgeschritten ist.

Zielbranche: Gesundheitswesen

OLIVO et KNAUF INDUSTRIES, (Kategorie Save Food)

Eine isotherme Transportlösung

Vom Ladungsträger zum Leistungsträger: FEURER Leichtbau KLT Typ 6 Ladungsträger müssen mehr können als eben „nur“ Ladung aufnehmen – so wie der FEURER Leichtbau KLT Typ 6. Die gemeinsame Entwicklung mit einem süddeutschen Automobilhersteller erlaubt ein sicheres und schnelles Beladen, Transportieren und Entladen ohne zusätzliche Sicherung. So werden Ladungsträger zu Leistungsträgern. Der KLT besteht komplett aus ultraleichtem EPP. Das erlaubt eine 100%ige Recycelbarkeit der Verpackung und bringt zudem eine Gewichtsreduzierungvon bis zu 70 %. Das macht sich positiv bemerkbar durch leichteres Handling und schnelleres Be- und Entladen, also mit geringeren Standzeiten der LKW und insgesamt reduzierten Frachtkosten. Obwohl die Ladungsträger nicht zusätzlich gesichert werden, überzeugen sie im Praxiseinsatz als besonders stabiles Gesamtsystem. Die Behälter werden zusammen mit einer Kunststoffabdeckung direkt auf Stahlflachpaletten gesetzt. Keine Stretchfolie, Spanngurte oder Bänder und damit auch keine zusätzlichen Kosten für deren Anschaffung, Handling und Entsorgung. Möglich wird das durch einen besonderen Stapelrand, die Verzahnung und die Fasen im EPP-Stapelbehälter. So erfüllt der KLT höchste Ansprüche an die Ladungssicherung. Die neuen EPP-Stapelbehälter sind bereits erfolgreich in der Praxis unterwegs. Sie sind DEKRA zertifiziert nach den VDI-Richtlinien 2700 ff und DIN-EN 12195-1 und zum Patent angemeldet.

Zielbranche: Lebensmittel